High chromium white cast iron grinding ball is also known as high chromium alloy casting ball, high chromium steel ball, referred to as high chromium ball. At present, most of the domestic wear-resistant material enterprises take the medium frequency electric furnace as the main body, and melt the high-quality scrap steel and chromium alloy material after reasonable matching; micro alloying treatment and quenching and tempering of molten iron; and then adopt unique metal mold and sand mold casting molding process; and then obtain martensite matrix after high-temperature quenching and tempering, so as to achieve high hardness and wear resistance 。

At present, high chromium ball is the main grinding medium used in cement industry in China. With the continuous development of cement grinding technology, the requirements of specific surface area and fineness of cement are higher, so it is very important for cement enterprises to select the right grinding materials.

High chromium alloy casting balls are widely used in powder preparation and ultra-fine deep processing of cement building materials, metal mines, coal slurry thermal power, chemical engineering, ceramic coatings, light industry paper, magnetic materials and other industries. The product has high hardness, low abrasion, good toughness and less crushing. In the process of use, the surface hardness of the ball will be further improved, and the wear resistance will be enhanced. At the same time, the production capacity of the mill can be improved, and the specific surface area of cement and the recovery rate of concentrate can be improved.

The abrasive body with high wear resistance can not only improve the grinding efficiency, reduce the time and times of ball repair and start-up and stop times, but also prolong the cleaning cycle and reduce the labor intensity of workers. At the same time, it is of great significance to improve the mill output per hour, ensure the abrasive quality, and reduce the power consumption and grinding body consumption. For example, Anhui Ningguo Chengxin wear-resistant materials Co., Ltd. developed chromium alloy casting ball products combined with different industries and working conditions, among which the forging hardness of high chromium ball for cement mill reaches above 62Hrc (impact value ≥ 4.0j/cm2). In many large-scale cement enterprises in China, the unit consumption per ton of cement in a single bin is only about 13g. Compared with the same period of the same period, the wear resistance of the cement mill is lower, and the chromium ball is increased by more than five times, which creates super value economic benefits for the cement enterprises. It can be described as the real environmental protection grinding ball and green grinding ball.

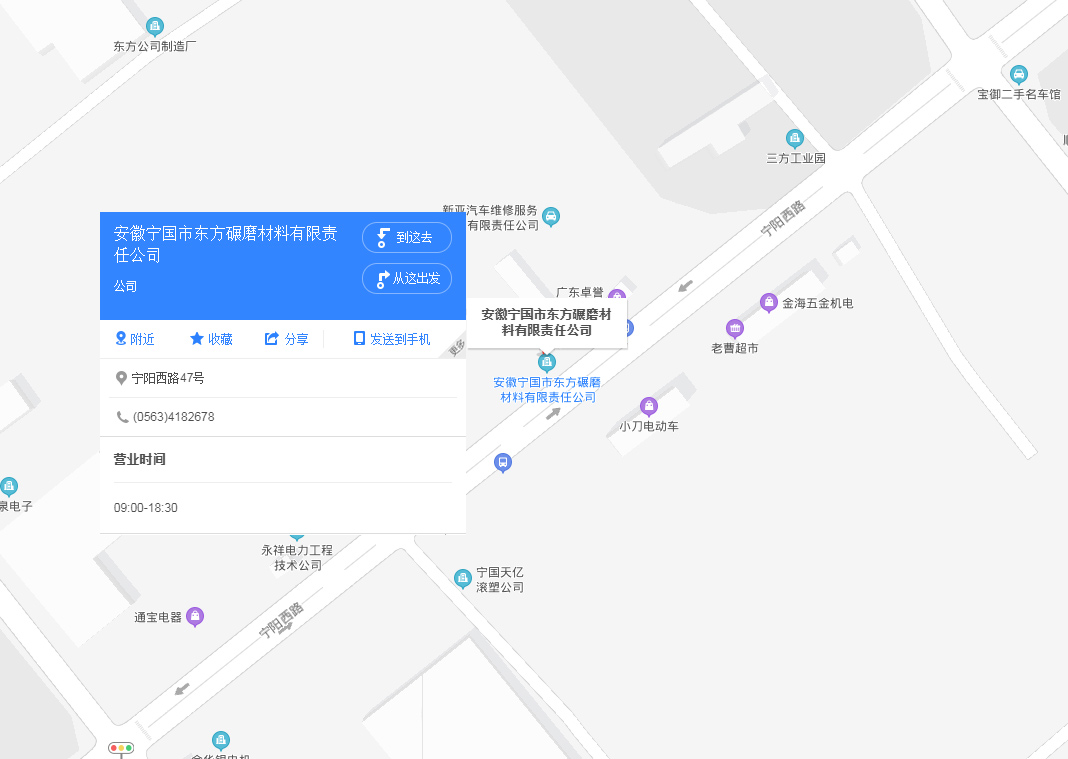

Address: No.47, Ningyang West Road, Ningguo City, Anhui Province

Sales Department:0563-4184901 web@ng-df.com

Manager of international trade department: Xiao Xingxian 18956398241 jeff@ng-df.com

Tel: 0563-4184866

Fax: 0563-4182677

Mobile

official account